The main company of the group is ATOMAT SPA. – Remanzacco – Italy. The company includes four plants:

- One dedicated to the roll production

- One dedicated to CNC machine production

- One dedicated to large lathes production

- One dedicated to the tool production

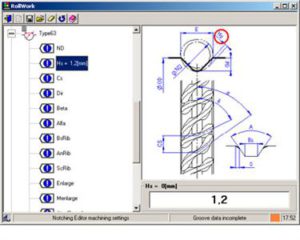

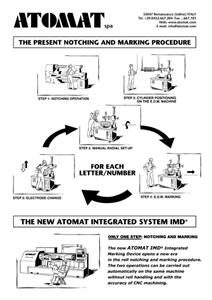

Today ATOMAT designs and manufactures CNC machines and relevant software dedicated to rolling mill roll maintenance shops.

All Atomat machines in all countries are assisted by remote teleservice and, when requested, by interventions at customer’s site. Atomat produces also the tools for its machine. The superior performance of Atomat Tools is the result of long experience and continuous testing.

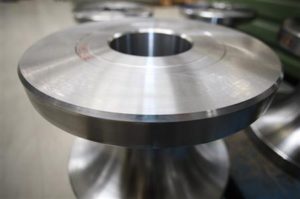

For roll production Atomat can provide design and manufacturing of steel and tungsten carbide rolls for several applications: welded tube, steel hot and cold rolling, copper and aluminium rolling, rolls for heating elements and guide rollers.

Quality is granted by the control of each single step in the roll production thanks also to the group synergy.